Emergency Case Study: Hidden Water Damage Discovery

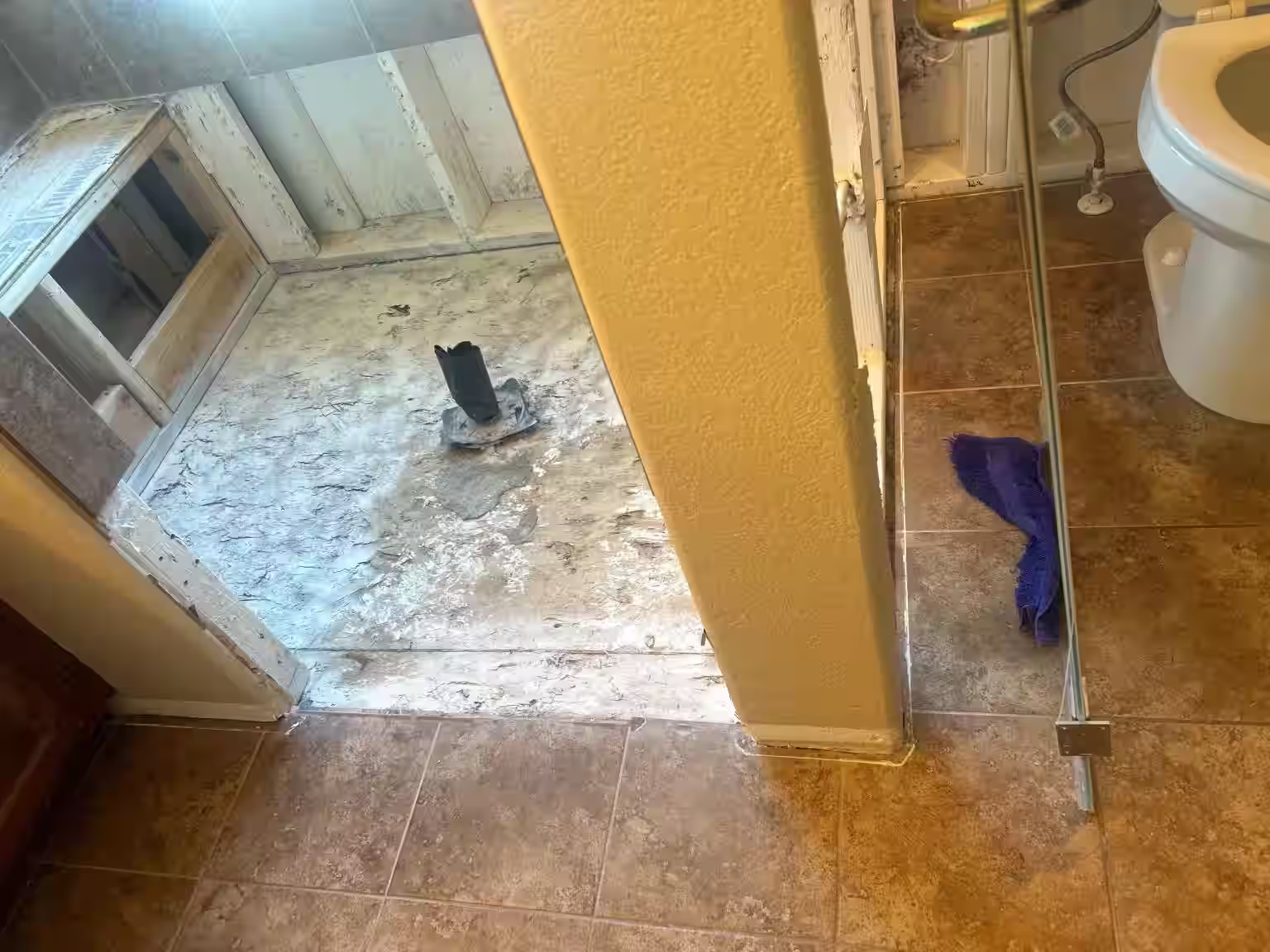

When this Commerce City homeowner noticed ceiling stains in their living room below the second-floor bathroom, they immediately called for professional assessment. What appeared to be minor water damage revealed a catastrophic shower pan failure that had been deteriorating for years. The investigation uncovered completely rotted subfloor, compromised framing, and extensive water damage to the ceiling below—requiring emergency demolition and complete structural reconstruction.

This project showcases our emergency water damage remediation capabilities, traditional TCNA-compliant mortar bed shower pan construction, and premium tile installation that transformed a disaster into a luxury bathroom that will last 50+ years. We worked directly with the homeowner's insurance to ensure code-compliant repairs while creating a stunning finished space.

The Emergency: Hidden Water Damage Discovered

The homeowner first noticed small water stains on their living room ceiling—directly below the second-floor bathroom shower. What seemed like a minor plumbing issue quickly escalated when our moisture inspection revealed catastrophic water damage:

- Complete shower pan failure - Original waterproof liner had deteriorated, allowing water to penetrate subfloor with every shower use for an estimated 3-5 years

- Rotted subfloor and framing - Plywood subfloor was completely saturated and deteriorated; floor joists showed early rot and required sister joist reinforcement

- Ceiling damage below - Living room ceiling drywall was saturated, showing mold growth and structural sagging requiring complete replacement

- Electrical hazard - Water had penetrated around recessed lighting in ceiling below, creating potential electrical safety issue

The original shower installation had used an inadequate vinyl liner with improper drain connection—a common failure point in 1990s-era construction. Without a proper pre-slope mortar bed, water pooled against the liner seams, eventually causing material deterioration and catastrophic failure.

Time was critical. We immediately coordinated with the homeowner's insurance adjuster, documented all damage with detailed photos and moisture readings, and began emergency water extraction and structural drying. The bathroom was completely unusable, requiring temporary facilities for the family during the 2-week reconstruction.

Our Solution: Complete Structural Rebuild with Traditional Mortar Bed

This emergency repair required complete demolition to the studs, structural remediation, and reconstruction using time-tested traditional mortar bed methods that would prevent any future failures. We followed TCNA Handbook method B415 and worked closely with Denver building inspectors to ensure code compliance for second-floor shower installations.

Demolition & Water Damage Remediation

We began with complete demolition, removing all tile, the failed shower pan, rotted subfloor, and damaged framing. Industrial dehumidifiers and air movers ran for 72 hours to eliminate all moisture from structural members.

- Removed all tile, membrane, and mortar down to studs and joists

- Replaced entire rotted subfloor with 3/4" exterior-grade plywood

- Installed sister joists to reinforce compromised floor framing

- Structural drying verified with moisture meters (<12% MC required)

- Coordinated electrician to repair recessed lighting and verify safety

Traditional Mortar Bed Shower Pan Construction

We constructed a code-compliant traditional mortar bed shower pan system—the gold standard for longevity and waterproofing. This two-part system creates multiple layers of protection against water penetration and will last 50+ years.

- Pre-slope mortar bed: Installed sloped deck mud layer (3:1 sand/cement mix) sloped 2% toward drain for proper drainage

- PVC waterproof membrane: 40-mil PVC liner installed over pre-slope, extending 12" up walls with proper corner folds and drain integration

- Drain assembly: Two-piece clamping drain sandwiches PVC liner for waterproof seal; tested with 24-hour flood test

- Top mortar bed: Reinforced setting bed (2" minimum thickness) sloped 4% toward drain, creating durable tile substrate

- Inspection & testing: Denver building inspector verified membrane integrity and slope; passed on first inspection

Learn more about proper shower floor slope requirements and why they're critical for preventing water damage.

Premium Natural Stone Tile Installation

With structural work and waterproofing complete, we transformed the shower into a luxury spa-like retreat featuring natural materials and timeless design.

- Natural pebble stone floor tile with slip-resistant surface and natural drainage

- Premium natural stone wall tile with horizontal stacked pattern

- Custom arched window integration maintaining waterproofing integrity

- Epoxy grout for maximum water resistance and minimal maintenance

- Penetrating sealer applied to natural stone for stain protection

Wall Waterproofing & Final Finishing

The final phase ensured complete waterproofing of all shower surfaces and installation of premium fixtures to complement the natural stone design.

- GoBoard cement backer on all walls for structural stability

- RedGard waterproofing membrane applied to all walls, ceiling, and curb

- Premium shower valve and fixtures with pressure-balancing for safety

- Schluter movement joints at all transitions for crack prevention

- Final water testing and inspection—passed on first attempt

Complete Reconstruction Gallery

From catastrophic water damage to luxury spa bathroom—follow the complete transformation with traditional mortar bed construction

Materials & Methods: TCNA-Compliant Construction

This emergency reconstruction followed Tile Council of North America (TCNA) Handbook method B415 and ANSI A108.1A standards for shower receptor construction. We used only premium, industry-proven materials with manufacturer warranties:

Why Traditional Mortar Bed vs. Pre-Fabricated Pans?

While foam or fiberglass pre-fabricated shower pans are faster to install, we chose traditional mortar bed construction for this project because it offers:

- Superior longevity: 50+ year lifespan vs. 20-25 years for foam systems

- Custom slope adjustment: Critical for second-floor installations where drainage is paramount

- Structural strength: Can support heavy natural stone tile without flexing

- Insurance preference: Many insurers require traditional methods for second-floor repairs due to proven reliability

- Code compliance: Meets all IRC and Denver building code requirements with inspectable construction stages

Results: From Disaster to Dream Bathroom

What began as a water damage emergency transformed into a stunning luxury bathroom that exceeded the homeowner's expectations. The complete reconstruction not only solved the catastrophic structural issues but created a spa-like retreat they'll enjoy for decades.

Technical Success

- Passed all Denver building inspections on first attempt

- 24-hour flood test confirmed zero water penetration

- TCNA-compliant construction ensures 50+ year lifespan

- Insurance claim fully covered structural repairs

Design Excellence

- Natural stone creates timeless spa-like aesthetic

- Pebble floor provides slip resistance and natural beauty

- Arched window preserved while maintaining waterproofing

- Low-maintenance materials reduce long-term upkeep

The homeowner was thrilled with how we transformed their emergency situation into an opportunity to create their dream bathroom. "We were devastated when we discovered the water damage, but South Denver Tile Experts walked us through every step—from insurance coordination to final inspection. The traditional mortar bed construction gives us complete peace of mind that we'll never face this problem again. The finished shower is absolutely stunning!"

Interested in our complete bathroom renovation services? Explore our portfolio of tile installation projects throughout the Denver metro area.

Emergency Shower Pan Repair FAQ

What causes shower pan failure and water damage?

Shower pan failure typically results from improper initial installation, aging materials, or structural settling. Common causes include inadequate waterproofing membrane installation, incorrect slope (less than 2% required), missing pre-slope layer in mortar bed systems, deteriorated rubber or vinyl liners, improperly sealed drain connections, and structural movement creating cracks. In this Commerce City case, the original shower pan had failed completely, allowing water to penetrate the subfloor and ceiling below. Second-floor shower failures are particularly critical because water damage affects living spaces below and can compromise structural integrity. According to TCNA (Tile Council of North America) standards, a properly constructed traditional mortar bed shower pan with PVC liner should last 30-50 years when installed correctly.

Should I repair or replace a failed shower pan?

When water damage is discovered, full shower pan replacement is almost always necessary rather than attempted repairs. Surface repairs cannot address underlying structural damage or failed waterproofing systems. In this project, we found extensive subfloor rot, compromised framing, and water damage to the ceiling below—all requiring complete demolition to the studs. Attempting to patch a failed shower pan is ineffective because: (1) you cannot access the waterproof membrane without demolition, (2) water has already compromised surrounding materials, (3) building codes require proper waterproofing for second-floor installations, and (4) insurance may not cover partial repairs if future leaks occur. Full replacement with modern materials and TCNA-compliant methods provides a permanent solution with proper warranties. While more expensive initially, complete reconstruction prevents ongoing damage and provides peace of mind for 30+ years.

What is a traditional mortar bed shower pan and why use it?

A traditional mortar bed shower pan is a time-tested two-part system that creates a sloped, waterproof shower floor. The process involves: (1) Pre-slope layer—a mortar bed sloped 2-4% toward the drain, (2) Waterproof membrane—40-mil PVC or CPE liner installed over the pre-slope and up the walls 8-12 inches, (3) Top mortar bed—a reinforced setting bed that creates the final slope and tile substrate. This method follows TCNA Handbook method B415 and ANSI A108.1A standards. We chose traditional mortar bed construction for this Commerce City project because it offers superior longevity (30-50+ years), allows custom slope adjustment critical for second-floor drainage, provides structural strength for heavy stone tile, enables precise integration with existing drain assembly, and is preferred by insurance companies for second-floor installations. While pre-fabricated foam pans are faster, mortar bed systems provide unmatched durability and customization for complex repairs.

How long does emergency shower pan repair take?

Emergency shower pan reconstruction with complete water damage remediation typically takes 2-3 weeks, depending on damage extent. This Commerce City project timeline was: Days 1-2: Complete demolition, damage assessment, and structural drying; Days 3-4: Subfloor and framing repair (rotted materials replaced); Days 5-6: Plumbing inspection and drain assembly installation; Days 7-8: Pre-slope mortar bed installation and curing (48 hours); Day 9: PVC waterproofing membrane installation and flood testing; Days 10-11: Top mortar bed installation and curing (48 hours); Days 12-13: Wall waterproofing (RedGard membrane) and prep; Days 14-16: Tile installation (walls and floor); Days 17-18: Grouting, sealing, and fixture installation; Day 19: Final inspection and testing. Emergency projects receive priority scheduling. The multi-day curing periods for mortar beds cannot be rushed—proper curing ensures structural integrity and prevents future failures. We coordinate with insurance adjusters and provide temporary bathroom solutions during construction.

Will my homeowners insurance cover shower pan water damage repair?

Homeowners insurance coverage for shower pan failure and water damage depends on the cause and policy specifics. Generally, insurance covers sudden and accidental water damage (like a catastrophic shower pan failure causing ceiling damage), but not gradual deterioration from lack of maintenance. In this Commerce City case, the homeowner's policy covered the emergency water damage remediation, structural repairs (subfloor, framing, ceiling below), and code-compliant shower pan reconstruction. Insurance typically does NOT cover upgrades to tile, fixtures, or cosmetic improvements beyond matching existing conditions. To maximize insurance coverage: (1) Document all water damage with photos immediately, (2) Contact insurance before demolition when possible, (3) Get professional water damage assessment, (4) Request code-compliant repairs (insurance must cover), (5) Separate emergency repairs from upgrades in estimates. We work directly with insurance adjusters, provide detailed documentation, and help homeowners navigate claims to ensure proper coverage for critical repairs while identifying what falls under normal renovation.

What building codes apply to second-floor shower pan installation in Denver?

Denver follows International Residential Code (IRC) with local amendments for second-floor shower installations. Key requirements include: Waterproofing—Shower pan must have waterproof membrane (PVC, CPE, or hot-mopped) extending 8-12 inches up walls, with RedGard or similar membrane on walls to ceiling in wet areas. Drainage slope—Minimum 2% (1/4 inch per foot) slope to drain; TCNA recommends 2-4% for optimal performance. Structural support—Floor framing must support 40 PSF live load plus weight of mortar bed and tile; we installed additional blocking and joists in this project. Drain assembly—Two-piece clamping drain required for membrane systems; must be accessible for service. Testing—24-hour flood test required before wall installation; inspector must verify membrane integrity. Ventilation—Bathroom exhaust fan required, ducted to exterior (not attic). This Commerce City project passed all inspections on first attempt because we followed TCNA Handbook methods and Denver building department standards. Proper permits and inspections are mandatory for second-floor shower work due to liability for water damage below.

What are signs my shower pan is failing and needs repair?

Warning signs of shower pan failure requiring immediate professional assessment include: Water damage below—Ceiling stains, paint peeling, or sagging drywall in room below shower (critical on second floor); Grout deterioration—Constant grout cracking or powdery grout that won't seal (indicates water behind tile); Musty odors—Persistent mildew smell even after cleaning suggests trapped water; Loose tiles—Floor tiles that move or sound hollow when tapped; Standing water—Water that doesn't drain properly or pools in corners; Caulk failure—Caulk around drain or curb that repeatedly fails despite replacement; Soft floor—Shower floor that feels spongy or flexes when walking. If you notice ANY of these signs on a second-floor shower, contact a professional immediately. This Commerce City homeowner initially noticed only grout discoloration, but investigation revealed catastrophic subfloor damage and ceiling compromise below. Early detection prevents extensive damage—a $3,000 shower pan replacement is far less expensive than $15,000+ in structural repairs, mold remediation, and ceiling reconstruction.

How do you prevent future shower pan failures?

Preventing shower pan failure requires proper initial installation and ongoing maintenance. Our installation prevention methods include: TCNA-compliant construction—Following Tile Council of North America Handbook method B415 for traditional mortar bed systems; Proper slope—Ensuring 2-4% slope throughout shower floor, not just to drain; Quality materials—Using 40-mil PVC membrane (not thin vinyl), reinforced mortar beds, and premium waterproofing; Flood testing—24-hour water test before wall installation to verify membrane integrity; Correct drain integration—Two-piece clamping drain with proper membrane attachment; Wall waterproofing—RedGard or Kerdi membrane on walls, not just relying on tile; Expansion joints—Proper movement joints at curb and wall transitions. Homeowner maintenance includes: Re-seal grout annually with penetrating sealer, replace caulk at curb/wall corners every 2-3 years, ensure proper bathroom ventilation (run fan during and 30 minutes after showers), address any cracks or loose tiles immediately, avoid harsh cleaning chemicals that deteriorate grout, and schedule professional inspection every 5 years for second-floor showers. This proactive approach extends shower pan life to 30-50+ years and prevents costly water damage emergencies.

Emergency Shower Pan Failure? We Can Help Immediately

Don't let water damage escalate. Our emergency response team provides rapid assessment, insurance coordination, and TCNA-compliant reconstruction that will last 50+ years.

Available 7 days a week • Insurance coordination • Free emergency assessment

Request Emergency Assessment

Noticed water stains, soft shower floor, or ceiling damage? Get immediate professional evaluation and competitive quote.