Emergency Shower Pan Repair: Structural Water Damage Restoration

Elizabeth, Colorado — Traditional PVC Liner Rebuild

The Hidden Danger

When mold appeared on the ceiling and walls of this Elizabeth, Colorado home, the homeowner had no idea they were standing on a shower floor that was slowly rotting away beneath their feet. Built in 2007, this shower had been silently leaking for years due to improper waterproofing during original construction. The structural damage was so severe that the homeowner was perhaps a year or two away from literally falling through the shower floor into the room below.

Project Overview

This project demonstrates why proper shower pan construction matters and why the traditional PVC liner method, when correctly installed per TCNA standards, remains one of the most reliable waterproofing systems available.

Location

Elizabeth, Colorado

Home Built

2007

Project Type

Emergency Shower Pan Repair

Timeline

Approximately 1 Week

Investment

$2,800

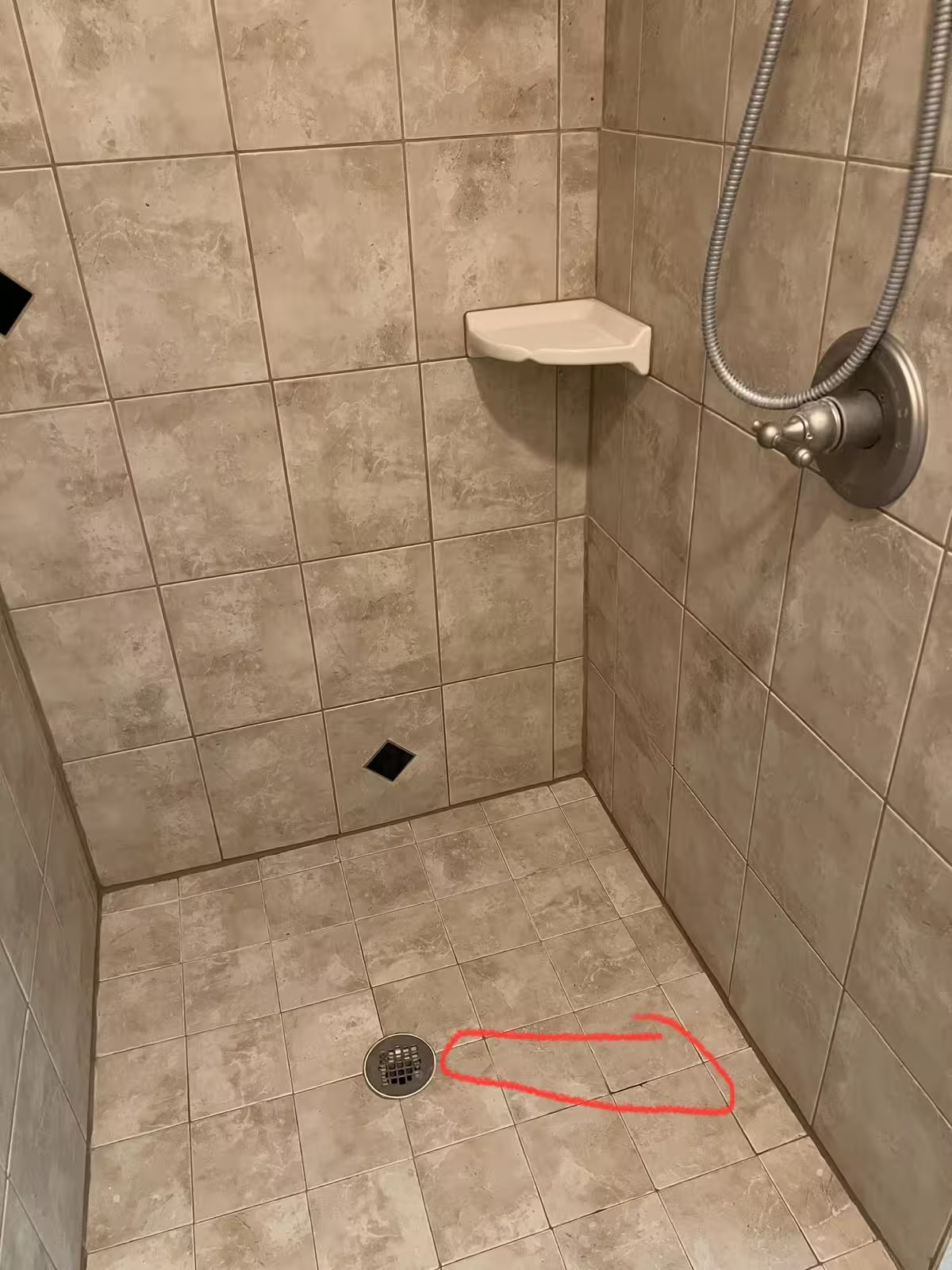

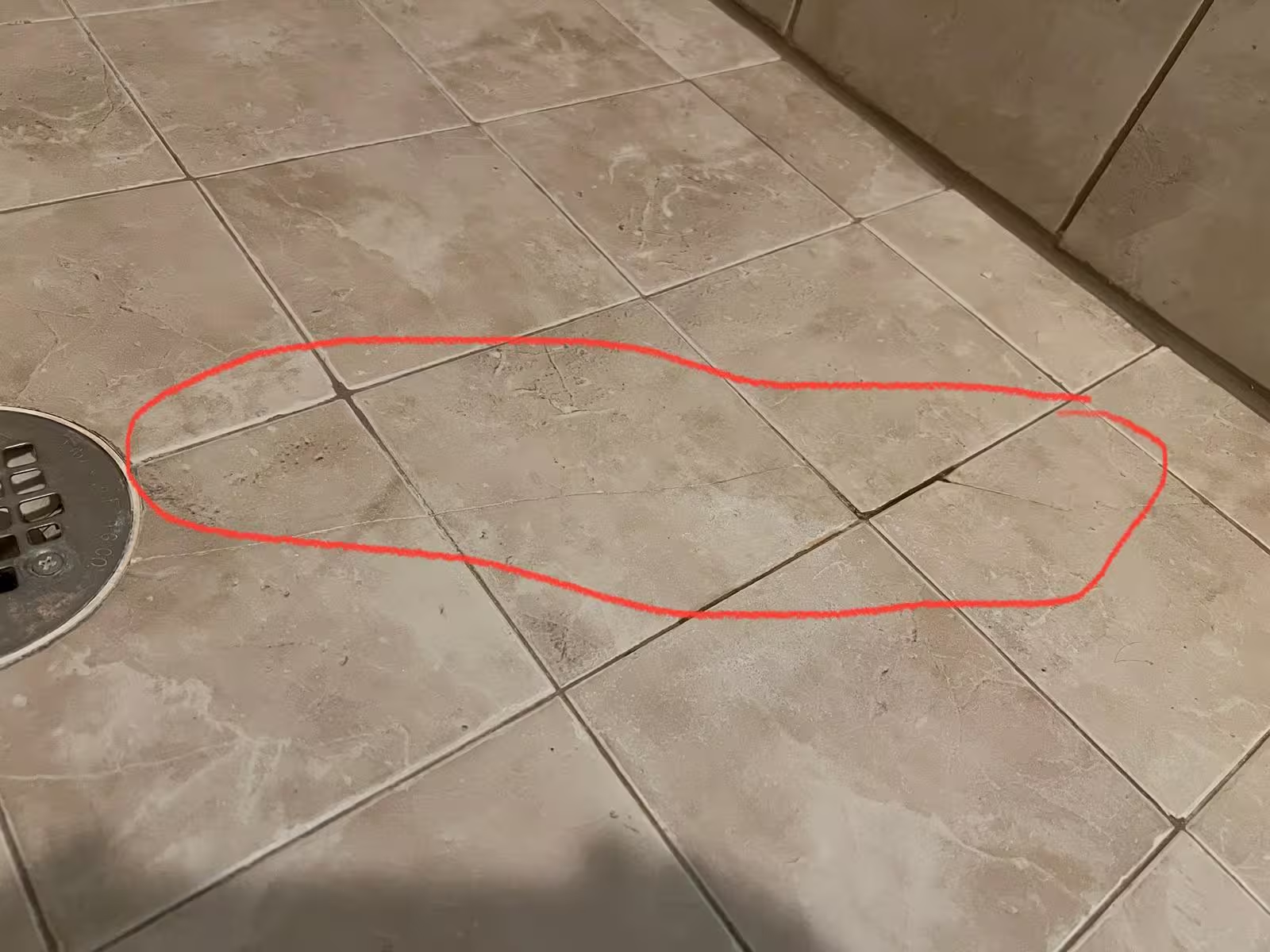

Before: Hidden Water Damage

The Challenge

The homeowner contacted us after discovering mold growth appearing on the ceiling below the second-floor bathroom and spreading to adjacent walls. Mold in these locations almost always indicates a water intrusion problem, and the shower is typically the primary suspect. We recommended opening the shower floor to investigate the source.

What we discovered was alarming. The original 2007 construction used a liquid waterproofing membrane applied directly to the subfloor—a method that can work when properly executed but requires meticulous application to ensure complete coverage. In this case, the liquid membrane had failed completely. Water had been penetrating through the tile and grout, bypassing the inadequate waterproofing, and saturating the plywood subfloor for nearly two decades.

The plywood had completely rotted. This was not merely a cosmetic problem or minor leak but a genuine structural emergency requiring immediate remediation.

Demolition: Revealing the Damage

Our Solution

Complete Demolition

We removed all tile from the shower floor, exposing the failed waterproofing system. The concrete mortar bed crumbled during removal, the plywood subfloor had turned soft and spongy from years of moisture exposure, and the floor joists showed early signs of rot damage.

Structural Repair

With the damaged materials removed, we cut out and replaced all compromised plywood, installing new OSB (oriented strand board) subflooring to restore structural integrity. We inspected all exposed floor joists for rot damage, treating any affected areas.

Traditional PVC Liner Installation

We installed a pre-slope mortar bed creating 1/4-inch per foot pitch toward the drain. Then a 40-mil PVC shower pan liner with corners folded (not cut) and extended 3+ inches above the curb. At the drain, 100% silicone sealant ensures a watertight seal while preserving weep holes.

Flood Test & Final Installation

Per TCNA guidelines, we performed a 24-hour flood test before proceeding. After passing inspection on the first attempt, we installed the final mortar bed with pea gravel around the drain to protect weep holes, followed by hexagon mosaic tile that coordinates with the existing wall tile.

Reconstruction: Building It Right

Technical Standards

This shower pan reconstruction adheres to multiple industry standards ensuring long-term waterproof performance.

TCNA B415

Mortar bed shower pan construction sequence

ANSI A108.1A

Mortar bed thickness and slope requirements

ASTM D4551

PVC liner material certification

IAPMO

Plumbing code for shower floor slope (1/4" to 1/2" per foot)

Materials and Methods

Why Liquid Membranes Sometimes Fail

This project illustrates a common failure mode with liquid-applied waterproofing membranes. While products like RedGard, HydroBan, and AquaDefense can provide effective waterproofing when properly applied, they require meticulous installation technique to work reliably.

Liquid Membrane Risks

- •Requires consistent thickness across entire area

- •Thin spots and pinholes create leak pathways

- •Coverage gaps impossible to verify after installation

PVC Liner Benefits

- •Creates impermeable physical barrier

- •Cannot develop thin spots or coverage gaps

- •30+ years of proven reliability when properly installed

The Results

The Elizabeth homeowner now has a shower built to standards that should have been followed during original construction. The traditional PVC liner installation provides reliable waterproofing backed by decades of proven performance. The structural subfloor replacement ensures the floor can safely support the shower for years to come.

More importantly, the mold problem that prompted this repair has been eliminated at its source. This project cost $2,800 and took approximately one week—a modest investment compared to the catastrophic structural failure that was imminent. The homeowner avoided what could have become a $15,000+ emergency repair involving collapsed flooring, extensive mold remediation, and potential injury.

Completed Restoration

Frequently Asked Questions

Common questions about shower pan leaks, repairs, and waterproofing methods

Don't Wait Until Your Shower Floor Fails

If you notice mold, water stains, or musty odors near your bathroom, your shower pan may be leaking. Early intervention prevents extensive structural damage and keeps repair costs manageable.

Related Services

Shower Pan Repair Commerce City

Expert shower pan leak repair and waterproofing restoration in Commerce City.

Learn MoreBathroom Renovation Castle Rock

Complete bathroom remodeling services in Castle Rock with custom tile work.

Learn MoreShower Remodeling Denver

Custom walk-in shower installations and complete shower renovations in Denver.

Learn MoreGet Your Free Shower Assessment

Serving Elizabeth, Parker, Castle Rock, Denver, Aurora, Littleton, Highlands Ranch, and surrounding Colorado communities.